HUICHUAN UBC Aluminum Can Recycling Production Line Solution

Classification:

Waste Solid Resource Recycling Production Line

Summary:

The company introduces international advanced technology and production inspection equipment. The development and design of products all adopt international advanced three-dimensional (3D) three-dimensional design.

Tel:

- Product Introduction

- Technical Parameter

- Cases

-

- Commodity name: HUICHUAN UBC Aluminum Can Recycling Production Line Solution

HUICHUAN UBC Aluminum Can Recycling Production Line SolutionHUICHUAN has deep expertise in the renewable resources equipment sector, focusing on the core crushing and sorting processes of UBC (used aluminum beverage cans). We provide customized solutions ranging from "equipment customization to whole-line construction," enabling efficient processing of pre-cleaned, dried loose cans or baled can blocks. Our solution minimizes aluminum loss to the greatest extent, accurately converting used aluminum cans into high-value recycled aluminum materials.I. Core Process: 5-Step Precision Handling to Maximize Aluminum Recovery ValueFor pre-processed used aluminum cans (either pre-cleaned, dried loose cans or baled blocks), we achieve efficient crushing and zero-waste sorting through a combination of customized equipmentCustom Dual-Shaft Shredder: Initial Size Reduction for Subsequent ProcessesIf the raw material is baled aluminum can blocks, they first enter the HUICHUAN custom dual-shaft shredder. Designed with "high torque and low speed," this shredder easily breaks down high-density bales into loose chunks of 5-10cm, preventing damage to subsequent equipment due to excessive hardness and preparing for fine crushing. If the raw material is pre-cleaned and dried loose cans, this step can be skipped directly to proceed to the next stage. 2. Vertical/Horizontal Crusher: Fine Crushing and Impurity SeparationThe material is fed into the HUICHUAN custom vertical or horizontal crusher (selected based on daily processing capacity). Targeting the structural characteristics of beverage cans—"aluminum body, iron lid, and plastic label"—a dedicated set of blades crushes the cans into uniform fragments of 1-3cm. During crushing, aluminum from the can body is initially separated from iron lids and plastic labels. Meanwhile, a built-in impurity screen filters out a small number of uncrushed large impurities. 3. Shaftless Roller Screen: Classification Screening to Optimize Sorting ConditionsThe crushed mixed fragments are conveyed to the shaftless roller screen. Using screens with different aperture sizes, the material is classified into two categories: "qualified aluminum fragments" and "fine impurities (e.g., sand and mud)." Qualified aluminum fragments move to the subsequent sorting process, while fine impurities are discharged directly—preventing blockages in sorting equipment and ensuring stable operation of the sorting system 4. Eddy Current Magnetic Separation Integrated Machine: Precise Separation of Aluminum and Metal ImpuritiesThe classified qualified material enters the HUICHUAN custom Eddy Current Magnetic Separation Integrated Machine—an upgraded all-in-one device that combines eddy current separation (for aluminum) and magnetic adsorption (for fine iron impurities) in a single unit, realizing "dual-function in one machine."For aluminum separation: It generates an eddy current effect through a high-frequency alternating magnetic field, applying a "repulsive force" to aluminum fragments to achieve instant separation from iron lids and other metal impurities.For fine iron removal: Equipped with a built-in high-performance neodymium magnet module, it adsorbs tiny iron particles (≤1mm) that are easily missed by conventional separators, eliminating hidden iron impurities in aluminum materials.Performance highlights: Sorting accuracy reaches over 99.7% (0.2% higher than single eddy current separators), and sorting efficiency is 25% higher than that of conventional equipment—ensuring no loss of core aluminum material and zero iron contamination. 5. Aluminum Dust Separation: Capturing Fine Powder to Eliminate WasteA dedicated aluminum dust separation step is added: using a combination of negative pressure suction and fine filters, aluminum fines (high-value materials easily overlooked) generated during crushing and sorting are accurately collected. This prevents waste caused by discharge along with dust or impurities. This step increases the overall aluminum recovery rate by an additional 1.2-1.5 percentage points, ensuring every piece of aluminum resource is monetized.II. Choose HUICHUAN, Gain a Head StartWhole-Line Service, Worry-Free ProcessWe offer more than just equipment—we act as a "full-process steward": from site surveys and capacity planning, to customized configuration of shredders, crushers, and Eddy Current Magnetic Separation Integrated Machines, to on-site installation and commissioning, we take the lead throughout the entire process. You only need to provide pre-processed raw materials and requirements, with no need for multi-party coordination. Our true "one-stop turnkey service" cuts 90% of detours from project launch to profit realization.Solid Quality, Rock-Steady ReliabilityDurability lies in the details: the core blades of shredders and crushers are made of high-toughness wear-resistant alloy; roller screens use thickened anti-corrosion steel; sensors in the sorting system (inclu

HUICHUAN UBC Aluminum Can Recycling Production Line Solution

HUICHUAN has deep expertise in the renewable resources equipment sector, focusing on the core crushing and sorting processes of UBC (used aluminum beverage cans). We provide customized solutions ranging from "equipment customization to whole-line construction," enabling efficient processing of pre-cleaned, dried loose cans or baled can blocks. Our solution minimizes aluminum loss to the greatest extent, accurately converting used aluminum cans into high-value recycled aluminum materials.

I. Core Process: 5-Step Precision Handling to Maximize Aluminum Recovery Value

For pre-processed used aluminum cans (either pre-cleaned, dried loose cans or baled blocks), we achieve efficient crushing and zero-waste sorting through a combination of customized equipment

- Custom Dual-Shaft Shredder: Initial Size Reduction for Subsequent Processes

If the raw material is baled aluminum can blocks, they first enter the HUICHUAN custom dual-shaft shredder. Designed with "high torque and low speed," this shredder easily breaks down high-density bales into loose chunks of 5-10cm, preventing damage to subsequent equipment due to excessive hardness and preparing for fine crushing. If the raw material is pre-cleaned and dried loose cans, this step can be skipped directly to proceed to the next stage.

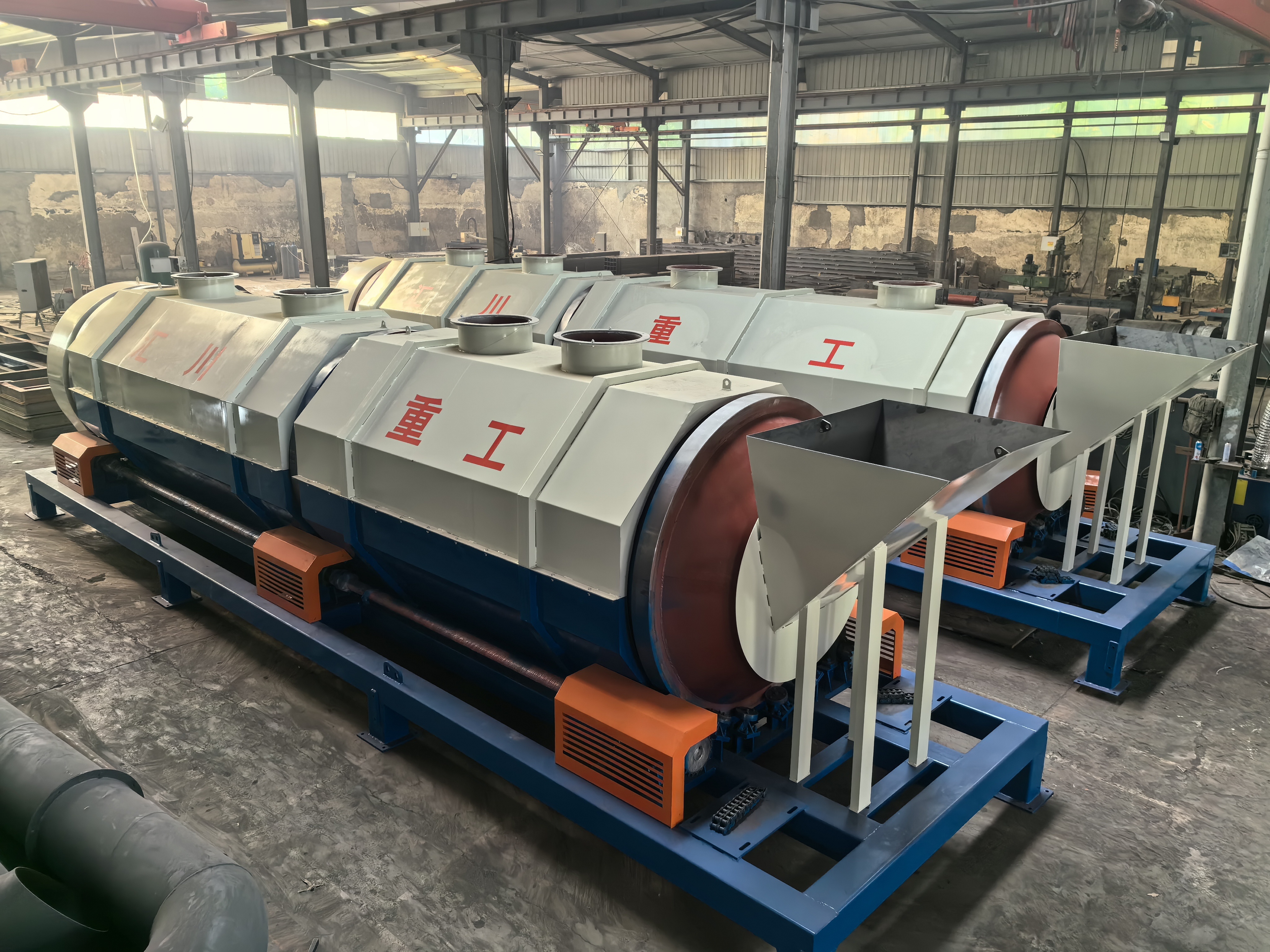

2. Vertical/Horizontal Crusher: Fine Crushing and Impurity Separation

The material is fed into the HUICHUAN custom vertical or horizontal crusher (selected based on daily processing capacity). Targeting the structural characteristics of beverage cans—"aluminum body, iron lid, and plastic label"—a dedicated set of blades crushes the cans into uniform fragments of 1-3cm. During crushing, aluminum from the can body is initially separated from iron lids and plastic labels. Meanwhile, a built-in impurity screen filters out a small number of uncrushed large impurities.

3. Shaftless Roller Screen: Classification Screening to Optimize Sorting Conditions

The crushed mixed fragments are conveyed to the shaftless roller screen. Using screens with different aperture sizes, the material is classified into two categories: "qualified aluminum fragments" and "fine impurities (e.g., sand and mud)." Qualified aluminum fragments move to the subsequent sorting process, while fine impurities are discharged directly—preventing blockages in sorting equipment and ensuring stable operation of the sorting system

4. Eddy Current Magnetic Separation Integrated Machine: Precise Separation of Aluminum and Metal Impurities

The classified qualified material enters the HUICHUAN custom Eddy Current Magnetic Separation Integrated Machine—an upgraded all-in-one device that combines eddy current separation (for aluminum) and magnetic adsorption (for fine iron impurities) in a single unit, realizing "dual-function in one machine."

- For aluminum separation: It generates an eddy current effect through a high-frequency alternating magnetic field, applying a "repulsive force" to aluminum fragments to achieve instant separation from iron lids and other metal impurities.

- For fine iron removal: Equipped with a built-in high-performance neodymium magnet module, it adsorbs tiny iron particles (≤1mm) that are easily missed by conventional separators, eliminating hidden iron impurities in aluminum materials.

- Performance highlights: Sorting accuracy reaches over 99.7% (0.2% higher than single eddy current separators), and sorting efficiency is 25% higher than that of conventional equipment—ensuring no loss of core aluminum material and zero iron contamination.

5. Aluminum Dust Separation: Capturing Fine Powder to Eliminate Waste

A dedicated aluminum dust separation step is added: using a combination of negative pressure suction and fine filters, aluminum fines (high-value materials easily overlooked) generated during crushing and sorting are accurately collected. This prevents waste caused by discharge along with dust or impurities. This step increases the overall aluminum recovery rate by an additional 1.2-1.5 percentage points, ensuring every piece of aluminum resource is monetized.

II. Choose HUICHUAN, Gain a Head Start

Whole-Line Service, Worry-Free Process

We offer more than just equipment—we act as a "full-process steward": from site surveys and capacity planning, to customized configuration of shredders, crushers, and Eddy Current Magnetic Separation Integrated Machines, to on-site installation and commissioning, we take the lead throughout the entire process. You only need to provide pre-processed raw materials and requirements, with no need for multi-party coordination. Our true "one-stop turnkey service" cuts 90% of detours from project launch to profit realization.

Solid Quality, Rock-Steady Reliability

Durability lies in the details: the core blades of shredders and crushers are made of high-toughness wear-resistant alloy; roller screens use thickened anti-corrosion steel; sensors in the sorting system (including the integrated machine) are equipped with high-precision chips; the magnetic module of the integrated machine adopts high-performance neodymium magnets (with a service life of up to 8 years). Additionally, we hold industry-leading patents for core processes such as eddy current magnetic separation integration. By selecting top-tier components and leveraging technical expertise, we increase the stability of continuous equipment operation by 40%, extend the service life of key components to 1.5 times the industry average, and minimize downtime and maintenance costs.

High Efficiency & Low Consumption, Tangible Profits

Compared with traditional production lines, we help you earn more in two ways: ① Processing efficiency is increased by over 30%, stably adapting to daily processing capacities from 10 tons to 200 tons for higher hourly output; the integrated machine saves 15% of floor space compared to separate eddy current and magnetic separation equipment, optimizing workshop layout. ② With the combination of the Eddy Current Magnetic Separation Integrated Machine and aluminum dust separation, the overall aluminum recovery rate exceeds 99.8% and impurity loss is ≤0.15%, directly reducing downstream smelting costs (e.g., reducing fuel consumption for impurity removal by 8-10%). Backed by these dual advantages, the investment payback period is shortened by 15-20% compared to the industry average, enabling faster return on investment.

Tailored Solutions, Flexible Adaptation

We reject "one-size-fits-all" approaches: whether you are a small-to-medium enterprise (SME) with a daily processing demand of 10 tons (matched with a horizontal crusher + compact Eddy Current Magnetic Separation Integrated Machine + small-scale dust collector) or a large-scale project with a daily capacity of 200 tons (equipped with a vertical crusher + large automated Eddy Current Magnetic Separation Integrated System + centralized dust collection unit), we can customize exclusive solutions based on your site size, budget, and long-term plans. This avoids overcapacity waste, reserves room for future upgrades, and ensures every investment is fully utilized.

-

Eddy Current Magnetic Separation Integrated Machine

Aluminum Dust Separation

-

Success Stories: HUICHUAN UBC Recycling Solutions Case Summary

Case Type

Location

Commissioning Time

Background

HUICHUAN Solution

Key Outcomes

Small-Scale Recycling Facility Transformation

Chonburi Province, Thailand (near Bangkok)

Q2 2023

Local startup with ~8 tons/day UBC intake; struggled with humid climate affecting equipment stability and low recovery rate (94%) via traditional tools.

Customized line: corrosion-resistant horizontal crusher + compact sorting line (with dehumidification module + aluminum dust separation).

Processing efficiency ↑32%; aluminum recovery rate ↑ to over 99.7%; equipment stable under humid conditions; profitability improved, enabling 50% capacity expansion in 8 months.

Mid-Sized Recycling Plant Upgrade

Osaka Prefecture, Japan

Q4 2022

Mid-sized plant handling 45 tons/day UBC; required strict compliance with Japan’s Waste Management Act (low emissions, noise control) and faced 1.6% impurity loss in aluminum.

Upgrade package: low-noise high-torque dual-shaft shredders + energy-saving vertical crushers + eddy current separator (with noise reduction cover) + multi-aperture shaftless roller screen.

Overall efficiency ↑38%; impurity loss ↓ to <0.2%; met Japan’s environmental standards (noise ≤65dB, emissions 15% below limit); secured long-term contracts with local beverage brands.

Large-Scale Industrial Project Implementation

Shandong Province, China (cooperated with a major industrial group)

Q1 2024

Needed a highly automated line for 200 tons/day UBC to build a state-of-the-art recycling complex.

Turnkey line: large-scale vertical crusher + automated sorting system (advanced sensors) + integrated aluminum dust collection unit + real-time monitoring system.

Processing efficiency 32% higher than industry standards; aluminum recovery rate consistently ≥99.9%; became a sustainable recycling showcase.

Expansion & Adaptability for Growing Business

Sichuan Province, China

Phase 1 (initial upgrade): Q3 2023; Phase 2 (capacity expansion): Q2 2024

Company aimed to double UBC capacity (15 tons/day → 30 tons/day) within 1 year.

Scalable plan: Phase 1: Upgrade with dual-shaft shredder + improved sorting system; Phase 2: Integrate larger vertical crusher + expanded aluminum dust separation unit.

Successfully doubled capacity on schedule; aluminum recovery rate improved; operating costs reduced.

Keywords:

Cases

Related Products

ENQUIRY NOW

If you have any comments or suggestions on our products, you can leave us a message. Please fill in the correct contact information, and we will contact you as soon as possible!