HUICHUAN X-ray sorter in minerals

Classification:

Sorting Machines

Summary:

The company introduces international advanced technology and production inspection equipment. The development and design of products all adopt international advanced three-dimensional (3D) three-dimensional design.

Tel:

- Product Introduction

- Technical Parameter

- Cases

-

- Commodity name: HUICHUAN X-ray sorter in minerals

X-ray sorters emits rays through an X-ray source to penetrate ores. After the detector receives the signals, it converts them into electrical signals, which are then processed by AI algorithms to achieve separation. Different minerals have different degrees of X-ray attenuation due to differences in density and elemental composition, thus distinguishing ore types and grades.

HUICHUAN X-ray sorter in minerals

Product overview:

X-ray sorters emits rays through an X-ray source to penetrate ores. After the detector

receives the signals, it converts them into electrical signals, which are then processed by AI algorithms to achieve separation. Different minerals have different degrees of X-ray

attenuation due to differences in density and elemental composition, thus distinguishing ore types and grades.

Core strengths

1. X-ray penetration combined with A1 intelligent fusion technology meets different operational requirements, achieving a sorting rate of over 90%.

2. 160 keV X-ray generator with power options of 500W, 800W, or 1200W, designed for achieving maximum material penetration.

3. Linear dual-energy detector with a pixel pitch of 0.6/1.6, used to achieve the highest imaging quality of materials.

4. Self-developed learning algorithms, with software programs and data continuously monitored to maintain optimal stability at all times.

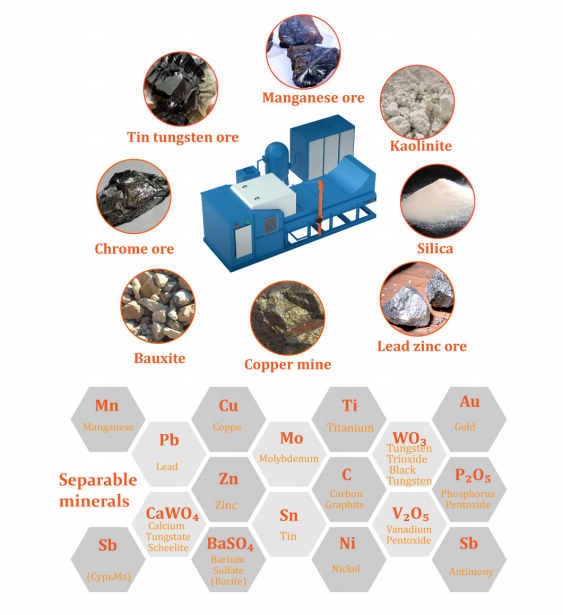

Scope of application

1. Non-ferrous metal: lead-zinc, copper, tungsten, bauxite, vanadium, antimony, tin, nickel, etc.

2. Ferrous metal: iron, manganese, etc.

3. Non-metallic and chemical: fluorite ore, phosphate ore, silica, kaolinite, oil shale, etc.

-

Model Selection of Standard Type XRT (Large Size 300-50mm)

Model XRT(IXS160BP

500)-12-300

XRT(IXS160BP

500)-16-300

XRT(IXS160BP

500)-20-300

XRT(IXS160BP

500)-24-300

XRT(IXS160BP

500)-32-300

XRT(IXS160BP

500)-40-300

Processing Capacity (t /h) 140 192 243 280 384 486 Note: The actual processing capacity is related to the mineral density. Different minerals process capacity selection coefficient are as follows:

Coefficient 1.0, fit for phosphate, vanadium, kaolinite, molybdenum, copper, zinc, tungsten, tin, antimony, gold, nickel, calcite, quartzite, limestone;

Coefficient 1.1, fit for fluorite and manganese;

Coefficient 1.2, fit for lead zinc, iron and barite.

For example: mineral type is iron, equipment model is XRT(IXS160BP500)-16-300-Fe, max processing capacity = 192 × 1.2 = 230 t/h

Model Selection of Standard Type XRT (Middle Size 100-25mm)

Model XRT(IXS160BP

500)-12-100

XRT(IXS160BP

500)-16-100

XRT(IXS160BP

500)-20-100

XRT(IXS160BP

500)-24-100

XRT(IXS160BP

500)-32-100

XRT(IXS160BP

500)-40-100

Processing Capacity (t/ h) 84 114 144 168 228 288 Note: The actual processing capacity is related to the mineral density. Different minerals process capacity selection coefficient are as follows:

Coefficient 1.0, fit for phosphate, vanadium, kaolinite, molybdenum, copper, zinc, tungsten, tin, antimony, gold, nickel, calcite, quartzite, limestone;

Coefficient 1.1, fit for fluorite and manganese;

Coefficient 1.2, fit for lead zinc, iron and barite.

For example: mineral type is iron, equipment model is XRT(IXS160BP500)-16-100-Fe, max processing capacity = 144 × 1.2 = 170 t/h

Model Selection of Standard Type XRT (Small Size 40-10mm)

Model XRT(IXS160BP 500 )-12-60 XRT(IXS160BP 500 )-16-60 XRT(IXS160BP 500 )-20-60 XRT(IXS160BP 500 )-24-60 XRT(IXS160BP 500)-32-60 XRT(IXS160BP 500)

-40-60

Processing Capacity (t/h) 35 48 60 70 96 120 Note: The actual processing capacity is related to the mineral density. Different minerals process capacity selection coefficient are as follows:

Coefficient 1.0, fit for phosphate, vanadium, kaolinite, molybdenum, copper, zinc, tungsten, tin, antimony, gold, nickel, calcite, quartzite, limestone; Coefficient 1.1, fit for fluorite and manganese;

Coefficient 1.2, fit for lead zinc, iron and barite.

For example: mineral type is iron, equipment model is XRT(IXS160BP500)-16-40-Fe, max processing capacity = 48 × 1.2 = 58

t/h

XRT Processing Capacity

Wide range of mineral size

XRT can process minerals within size range from 350mm to 10mm.

Various models of equipment

XRT belt distributor width can be from 1m to 4m, creating the most economical solution based on different capacity demands of enterprises.

Large process capacity

Belt speed can reach 4 m/s, maximum process capacity of a singe equipment can reach 500 t/h.

Keywords:

Pre

Next

Cases

Related Products

ENQUIRY NOW

If you have any comments or suggestions on our products, you can leave us a message. Please fill in the correct contact information, and we will contact you as soon as possible!