Eddy current separator

Classification:

Sorting Machines

Summary:

The company introduces international advanced technology and production inspection equipment. The development and design of products all adopt international advanced three-dimensional (3D) three-dimensional design.

Tel:

- Product Introduction

- Technical Parameter

- Cases

-

- Commodity name: Eddy current separator

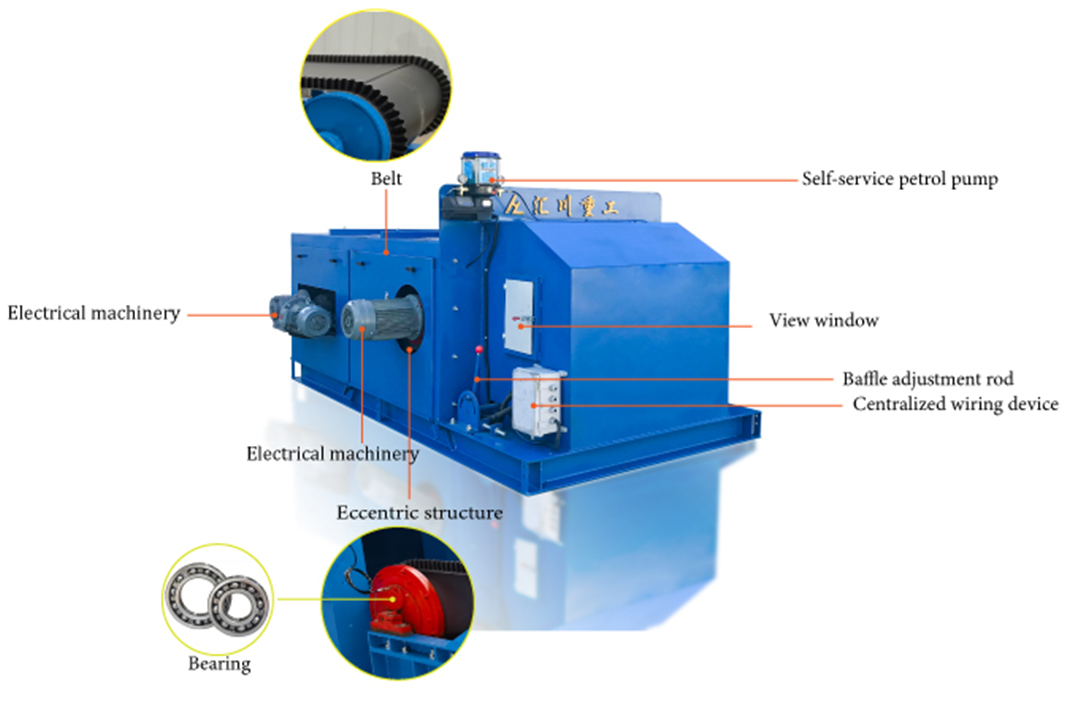

The eddy current sorter is a device that separates non-ferrous metal substances from non-metallic substances with precision. It is divided into three structures of high frequency multi-pole, eccentric and concentric.

Introduction:

Eddy current separator is a device that can accurately separate non-ferrous metal substances from non-metallic substances. There are two types of structures: concentric and eccentric. Huichuan mainly produces eccentric structure sorting machines, which are further divided into multipole and standard types according to the sorting requirements of different materials.

Huichuan eddy current separators have nearly 3,000 application cases all over the world, spreading across Asia, Australia, the Middle East, Africa, Europe and America. They are convincing by virtue of their highly accurate separation efficiency and durability.

Technical advantages:

- Eccentric structure+multi magnetic pole fusion technology, meeting different working conditions requirements, with a sorting rate of over 99%.

- Intelligent lubrication system effectively avoids bearing damage caused by unstable oil injection, ensuring stable operation of the equipment.

- Modular structural design, used to achieve rapid belt replacement.

- After size classification, our equipment can highly accurately adapt to sortable materials with fine particle sizes (as fine as 0.3mm). For particles with a size of 0mm-5mm, the sorting accuracy can reach more than 85%, for particles with a size of 5mm-8mm, the sorting accuracy can reach more than 95%, and for particles with a size of more than 8mm, it can reach more than 99.5%.

Applicable materials:

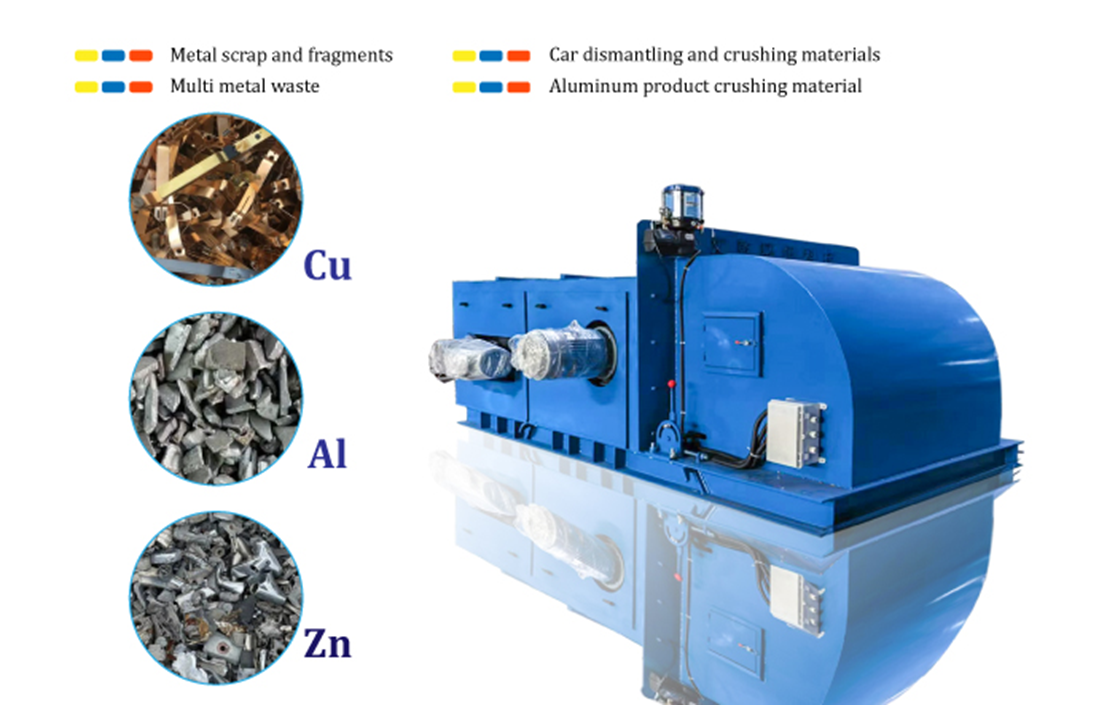

Materials containing non-ferrous metals such as copper, aluminum, zinc and magnesium

Non ferrous metals (copper, aluminum, zinc, magnesium) will jump out along their conveying direction due to repulsive interactions; Realize separation from non-metallic substances such as glass, plastic, rubber, etc.

Application scenarios:

Following processes such as crushing, classification, and magnetic separation, the eddy current separator can recover clean, marketable metal mixtures containing aluminum, copper, zinc, brass, etc. Its applications span various non-ferrous metal recycling scenarios, including shredded waste, construction debris, municipal solid waste, packaging waste, incineration bottom ash, aluminum salt slag, e-waste, wood chips, glass, and foundry sand.

Detailed images:

-

Technical ParametersType

Effective Magnetic Width(mm)

Handling Capacity(T/h)

Total Power (KW)

HPFX-10

800

4-6

6.7

HPFX-12

1000

6-8

8.2

HPFX-14

1200

8-10

8.2

HPFX-16

1500

10-12

8.44

HPFX-18

1600

12-14

11.6

HPFX-20

1800

14-16

15.5

HPFX-22

2000

18-20

15.5

-

Case 1: Electronic Waste (WEEE) Recycling

Scenario: A recycling plant processes 50 tons/day of shredded PCBs and plastic casings from old computers.

Equipment Used: ECS-1200 Eddy Current Sorter (Processing Width: 1200mm, Capacity: 10-15 t/h).

Outcome:- Separates 98% of aluminum heat sinks and copper wires from plastic mixtures.

- Increases metal recovery value by $120/ton compared to manual sorting.

- Reduces labor costs by 70% with automated high-speed sorting.

Case 2: Construction & Demolition (C&D) Waste

Scenario: A waste management company handles mixed C&D debris containing steel, aluminum, and concrete fragments.

Challenge: Manual separation of 50mm aluminum scraps from 200 tons/day of waste was inefficient.

Solution: ECS-800 Sorter (Power: 15kW, Dimensions: 3200×1800×1600mm).

Result:- Processes 8 tons/hour, achieving 95% aluminum purity.

- Decreases transportation costs by 40% due to reduced waste volume.

- Pays back equipment investment within 6 months through recycled metal sales.

Case 3: Mining Ore Beneficiation

Scenario: A tin mine needs to separate non-ferrous metals from ore tailings.

Equipment Parameters: ECS-1200 with adjustable magnetic field intensity (up to 1.2T).

Impact:- Recovers 2.5 tons/day of valuable copper and zinc from 100 tons of tailings.

- Increases overall ore utilization rate from 68% to 89%.

- Reduces water consumption in traditional washing processes by 35%.

Case 4: Glass Recycling Plant

Scenario: A glass recycling facility removes aluminum caps and steel residues from crushed glass cullet.

Solution: ECS-800 Sorter (Net Weight: 1800kg) integrated into the conveyor line.

Key Benefits:- Ensures <0.1% metal contamination in final glass products.

- Increases production line speed from 300 to 500 tons/day.

- Maintains 99.5% separation efficiency after 24/7 operation for 18 months.

Keywords:

Cases

Related Products

ENQUIRY NOW

If you have any comments or suggestions on our products, you can leave us a message. Please fill in the correct contact information, and we will contact you as soon as possible!