vertical air separator

Classification:

Sorting Machines

Summary:

The company introduces international advanced technology and production inspection equipment. The development and design of products all adopt international advanced three-dimensional (3D) three-dimensional design.

Tel:

- Product Introduction

- Technical Parameter

- Cases

-

- Commodity name: vertical air separator

Huichuan Vertical Air Separator(ZigZag Separator)

As an industry-leading equipment in the field of solid waste resource recovery, Huichuan Vertical Air Separator (also known as Huichuan Air Sorting Machine) has become a core equipment in the solid waste sorting and recycling process by virtue of cutting-edge aerodynamic application technology. Through precisely controlled wind force, it efficiently separates light and floating materials (such as plastic films, paper, and flocs) from heavy materials (such as metals, bricks, and glass) in solid waste. This lays a solid foundation for subsequent sorting equipment (such as magnetic separators and screening machines) to maximize resource recovery, significantly reduces the complexity and cost of the overall processing flow, and leads the development of solid waste sorting technology towards high efficiency and precision.

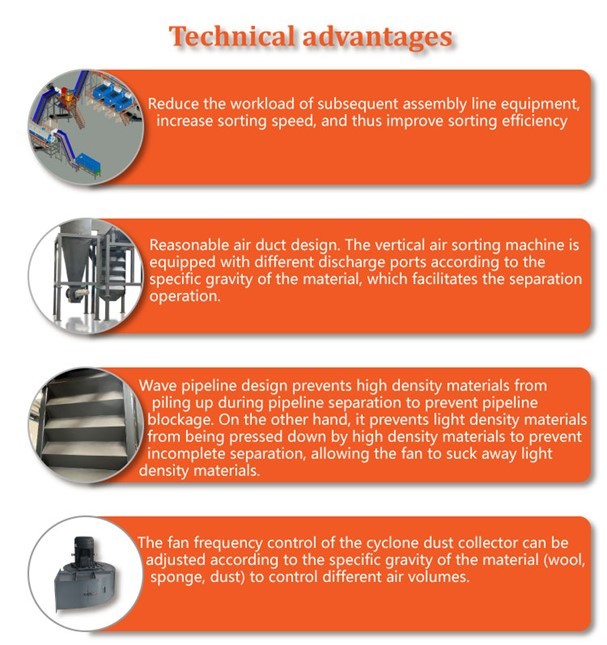

Technical Advantages

- Reduce the workload of subsequent assembly line equipment, increase the sorting speed, and thus improve the sorting efficiency.

- Reasonable air duct design. The vertical air sorting machine is equipped with different discharge ports according to the specific gravity of materials, which facilitates the separation operation.

- Frequency conversion control for the fan of the cyclone dust collector: Allows adjustment of air volume according to the specific gravity of materials (such as lint, sponge, and dust).

- Wave-shaped pipeline design: Prevents heavy materials from piling up and blocking the pipeline during separation; meanwhile, avoids light materials being pressed by heavy ones (which would cause incomplete separation), ensuring light materials are effectively sucked away by the fan.

- Low noise, high throughput, and sorting efficiency up to 95% and above.

-

-

1. Municipal Solid Waste TreatmentA large municipal waste treatment plant introduced the Huichuan Vertical Air Separator. After pretreatment, the recovery rate of light materials such as plastics and paper exceeded 90%. The processing capacity of subsequent equipment was reduced, the process cost was lowered by 25%, and garbage resource utilization was promoted.2. Industrial Solid Waste RecyclingElectronic waste recycling enterprises use it to separate plastics and metals. The plastic recovery rate is over 92%, and the metal purity reaches 95%, which improves the recycling efficiency and achieves a win-win situation of economic and environmental benefits.3. End-of-Life Vehicle RecyclingAutomobile dismantling plants use the Huichuan Vertical Air Separator to process mixed waste after dismantling. It can efficiently separate plastic parts (such as bumper fragments, interior foam) from metal parts (such as steel frame fragments, copper cables). The plastic recovery purity reaches 90%, the metal separation efficiency is increased by 25%, and the manual sorting cost is greatly reduced.4. Construction Waste TreatmentA construction waste recycling project adopted this equipment to separate light thermal insulation materials, plastic sheets from concrete blocks and bricks in demolition waste. The removal rate of light substances exceeded 93%, providing pure raw materials for the recycling of heavy aggregates and increasing the resource utilization rate of construction waste to over 85%.

1. Municipal Solid Waste TreatmentA large municipal waste treatment plant introduced the Huichuan Vertical Air Separator. After pretreatment, the recovery rate of light materials such as plastics and paper exceeded 90%. The processing capacity of subsequent equipment was reduced, the process cost was lowered by 25%, and garbage resource utilization was promoted.2. Industrial Solid Waste RecyclingElectronic waste recycling enterprises use it to separate plastics and metals. The plastic recovery rate is over 92%, and the metal purity reaches 95%, which improves the recycling efficiency and achieves a win-win situation of economic and environmental benefits.3. End-of-Life Vehicle RecyclingAutomobile dismantling plants use the Huichuan Vertical Air Separator to process mixed waste after dismantling. It can efficiently separate plastic parts (such as bumper fragments, interior foam) from metal parts (such as steel frame fragments, copper cables). The plastic recovery purity reaches 90%, the metal separation efficiency is increased by 25%, and the manual sorting cost is greatly reduced.4. Construction Waste TreatmentA construction waste recycling project adopted this equipment to separate light thermal insulation materials, plastic sheets from concrete blocks and bricks in demolition waste. The removal rate of light substances exceeded 93%, providing pure raw materials for the recycling of heavy aggregates and increasing the resource utilization rate of construction waste to over 85%.

Keywords:

Cases

Related Products

ENQUIRY NOW

If you have any comments or suggestions on our products, you can leave us a message. Please fill in the correct contact information, and we will contact you as soon as possible!