Recycled aluminum plate

Classification:

Circular Upcycled Architecture and decorative Products

Summary:

The company introduces international advanced technology and production inspection equipment. The development and design of products all adopt international advanced three-dimensional (3D) three-dimensional design.

Tel:

- Product Introduction

- Technical Parameter

- Cases

-

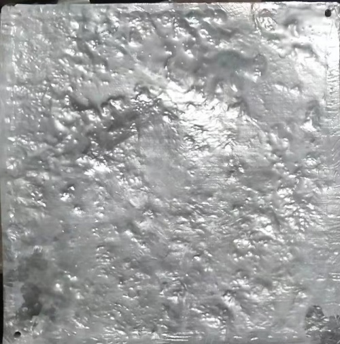

- Commodity name: Recycled aluminum plate

The recycled aluminum plate used in Shenzhen Taiziwan New World Cultural Shopping Mall is made of 100% recycled aluminum material

Introduction and production process of recycled aluminum plate

The recycled aluminum plate used in Shenzhen Taiziwan New World Cultural Shopping Mall is made of 100% recycled aluminum material, which is remelted and cast into the recycled aluminum plate used in the project.

Recycling process of raw materials for recycled aluminum plates

Processed recycled aluminum ingots.

Preparation of aluminum casting mold substrate and mold forming by dewaxing method

The molding of recycled aluminum plates requires molds. The substrate of the mold needs to be cast using dewaxing method due to the large number of patterns.

The mold substrate produced by dewaxing casting method needs to be embedded into a pre processed aluminum alloy mold kit as the mold for aluminum sand casting method.

*Sand mold production

The pre made metal cast aluminum mold needs to be replicated onto special mineral sand and stacked into a sand mold.

*Sand mold cast aluminum

Pour aluminum water into the prepared sand mold and complete the casting process of recycled aluminum plate by the gravity of aluminum metal.

*Sheet metal processing and surface treatment

The melted and cast recycled aluminum plate needs to undergo sheet metal processing such as grinding and punching for easier installation. Afterwards, surface treatment needs to be completed through processes such as degreasing, cleaning, drying, spraying, and baking. Then pack it up. -

Green Skyscraper Project in New YorkA renowned architectural firm in New York aimed to construct a state - of - the - art skyscraper that not only made a bold architectural statement but also adhered to strict environmental sustainability standards. Our recycled aluminum plates were selected as a key material for the building's facade.The lightweight property of the recycled aluminum plates significantly reduced the structural load of the skyscraper, enabling a more efficient and cost - effective building design. The high strength and durability of the plates ensured that the facade could withstand harsh weather conditions, including strong winds and heavy snowfall, common in New York. The excellent corrosion resistance protected the plates from urban pollutants and acid rain, maintaining the building's aesthetic appeal over time.Moreover, the form ability of the recycled aluminum plates allowed the architects to create a unique, wave - like pattern on the facade, which became a distinctive feature of the building. By using our recycled aluminum plates, the project achieved a significant reduction in its carbon footprint, as recycling aluminum for the facade consumed far less energy compared to using virgin aluminum. This green building project not only won multiple architectural awards but also became a model for sustainable urban construction.

Electric Vehicle Body Production by a European AutomakerA leading European electric vehicle manufacturer was seeking to enhance the performance and sustainability of its new electric vehicle models. Our recycled aluminum plates were incorporated into the production of the vehicle bodies.The high strength - to - weight ratio of the recycled aluminum plates played a crucial role in reducing the overall weight of the electric vehicles. This weight reduction led to a significant improvement in the vehicles' energy efficiency, increasing their driving range on a single charge. The durability of the plates ensured that the vehicle bodies could withstand daily driving impacts and maintain their structural integrity over the long term.In the production process, the form ability of the recycled aluminum plates allowed for the creation of complex and aerodynamic body shapes, optimizing the vehicle's performance and appearance. By choosing our recycled aluminum plates, the automaker not only met its sustainability goals by using recycled materials but also improved the competitiveness of its electric vehicle products in the market. The new electric vehicle models, featuring our recycled aluminum plates, received high praise from consumers for their excellent performance and eco - friendly features.

Keywords:

Pre

Next

Cases

Related Products

ENQUIRY NOW

If you have any comments or suggestions on our products, you can leave us a message. Please fill in the correct contact information, and we will contact you as soon as possible!