Metal Scrap Recycling Production Line

Classification:

Waste Solid Resource Recycling Production Line

Summary:

The company introduces international advanced technology and production inspection equipment. The development and design of products all adopt international advanced three-dimensional (3D) three-dimensional design.

Tel:

- Product Introduction

- Technical Parameter

- Cases

-

- Commodity name: Metal Scrap Recycling Production Line

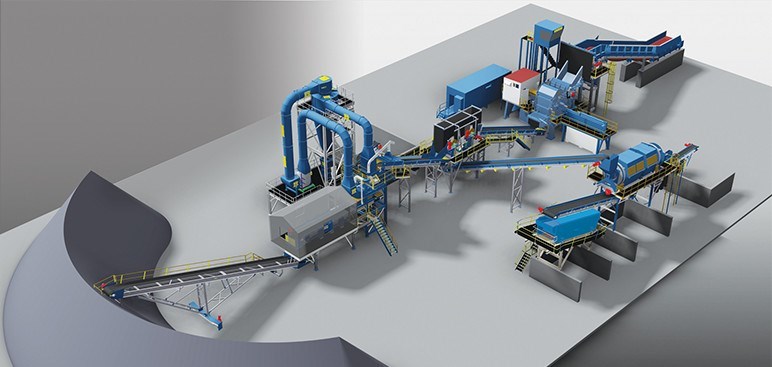

The entire production line consists of a feeding conveyor, a host, a discharge conveyor, a magnetic separation conveyor, a sorting conveyor, dust removal, and an operation cabinet. The crushed materials from the scrap steel crusher are separated from ferrous metal, non-ferrous metal, and non-metallic materials through vibration conveyors, belt conveyors, and magnetic sorting systems, and sent out for stacking by their respective conveyors.

Process flow:

The entire production line consists of a feeding conveyor, a host, a discharge conveyor, a magnetic separation conveyor, a sorting conveyor, dust removal, and an operation cabinet. The crushed materials from the scrap steel crusher are separated from ferrous metal, non-ferrous metal, and non-metallic materials through vibration conveyors, belt conveyors, and magnetic sorting systems, and sent out for stacking by their respective conveyors. Non ferrous metals and non-metallic materials are once again searched by magnetic separation equipment on the conveyor, picking out free iron metal materials to improve the recovery rate of iron metal materials. At the same time, by manually selecting non-ferrous metals, the recovery efficiency can be improved. The entire scrap steel line is monitored by an upper computer and controlled by a PLC, which can achieve microcomputer control and manual operation.

Product Features

Ultra high crushing efficiency

The entire equipment adopts hydraulic feeding and a combination of hammer and ring hammer to break the hammer head, which increases the efficiency by 5% -15% compared to other crusher equipment.

Perfect finished product particles

Adopting a unique roller kneading process, it significantly removes dirt such as paint and forms high-density ball like materials, increasing the value by over 30%.

Stable operational capability

Set up a safety door. After the non crushable object enters the crushing chamber, the operator can open the safety door and discharge it from the machine body to avoid damaging the crusher.

Advanced control system

The PLC control system and hydraulic power system enable intelligent production to save time and effort, achieving stable, automatic, and safe operation of the entire production line.

-

Case 1: Transforming Automotive Manufacturing Waste Management

A leading automotive manufacturer in Europe was grappling with a substantial amount of metal scrap generated during its production processes, including stamping, machining, and assembly. The company previously used a fragmented recycling approach, which involved manual sorting and basic processing, resulting in low recovery rates of valuable metals and high disposal costs. Additionally, the lack of proper separation led to the loss of precious materials like aluminum, copper, and high - grade steel.

After implementing our advanced Metal Scrap Recycling Production Line, the manufacturer witnessed a significant transformation. The production line, with a processing capacity of 15 tons per hour, was equipped with state - of - the - art shredding, magnetic separation, eddy - current separation, and hydraulic pressing technologies. First, the metal scrap entered the high - speed shredder, which broke it into small, uniform pieces, facilitating subsequent separation. The magnetic separator efficiently removed ferrous metals, while the eddy - current separator targeted and separated non - ferrous metals such as aluminum and copper with precision.

In the first year of operation, the company achieved a remarkable 85% recovery rate of valuable metals, compared to the previous 40%. This increase in recovery not only reduced the demand for virgin metal materials by 30% but also saved approximately $3.5 million annually in raw material procurement costs. Moreover, the recycled metals were of high quality, meeting the stringent standards required for automotive component manufacturing. The compacted metal bales produced by the hydraulic press were easy to store and transport, further optimizing the recycling process. The environmental impact was also greatly mitigated, as the reduced reliance on virgin metals decreased energy consumption and carbon emissions associated with metal production.Case 2: Optimizing Operations for a Large - scale Metal Recycling Company

A major metal recycling firm in North America was facing intense competition and inefficiencies in its existing recycling operations. The company struggled to handle a diverse range of metal scrap, including construction debris, discarded machinery parts, and end - of - life vehicle components, with its outdated equipment. The manual sorting process was labor - intensive, time - consuming, and prone to errors, leading to suboptimal material recovery and lower profit margins.

To address these challenges, the company installed our customized Metal Scrap Recycling Production Line with a processing capacity of 20 tons per hour. The production line incorporated an intelligent sorting system that used optical sensors and artificial intelligence algorithms to identify and separate different types of metals based on their chemical composition and physical properties. This advanced sorting technology, combined with mechanical shredding and multiple separation stages, significantly improved the accuracy and efficiency of the recycling process.

Post - implementation, the recycling company saw a 60% increase in its daily processing volume of metal scrap. The recovery rate of valuable metals soared to 90%, enabling the company to extract and sell more recycled materials, which in turn increased its annual revenue by $5 million. The automated operation of the production line reduced labor costs by 45% and minimized the risk of workplace injuries associated with manual handling. Additionally, the company was able to expand its service offerings to include more complex metal recycling projects, enhancing its competitiveness in the market. The consistent quality of the recycled metals also attracted new customers from various industries, further solidifying its position as a leading metal recycling provider.

Keywords:

Cases

Related Products

ENQUIRY NOW

If you have any comments or suggestions on our products, you can leave us a message. Please fill in the correct contact information, and we will contact you as soon as possible!