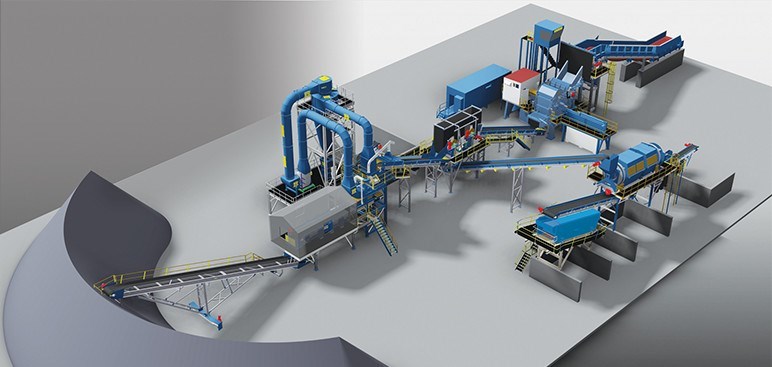

Metal Scrap Recycling Production Line

The entire production line consists of a feeding conveyor, a host, a discharge conveyor, a magnetic separation conveyor, a sorting conveyor, dust removal, and an operation cabinet. The crushed materials from the scrap steel crusher are separated from ferrous metal, non-ferrous metal, and non-metallic materials through vibration conveyors, belt conveyors, and magnetic sorting systems, and sent out for stacking by their respective conveyors.

Key words:

Metal Scrap Recycling Production Line

Classification:

Waste Solid Resource Recycling Production Line

E-mail:

WhatsApp:

Metal Scrap Recycling Production Line

Process flow:

The entire production line consists of a feeding conveyor, a host, a discharge conveyor, a magnetic separation conveyor, a sorting conveyor, dust removal, and an operation cabinet. The crushed materials from the scrap steel crusher are separated from ferrous metal, non-ferrous metal, and non-metallic materials through vibration conveyors, belt conveyors, and magnetic sorting systems, and sent out for stacking by their respective conveyors. Non ferrous metals and non-metallic materials are once again searched by magnetic separation equipment on the conveyor, picking out free iron metal materials to improve the recovery rate of iron metal materials. At the same time, by manually selecting non-ferrous metals, the recovery efficiency can be improved. The entire scrap steel line is monitored by an upper computer and controlled by a PLC, which can achieve microcomputer control and manual operation.

Product Features

Ultra high crushing efficiency

The entire equipment adopts hydraulic feeding and a combination of hammer and ring hammer to break the hammer head, which increases the efficiency by 5% -15% compared to other crusher equipment.

Perfect finished product particles

Adopting a unique roller kneading process, it significantly removes dirt such as paint and forms high-density ball like materials, increasing the value by over 30%.

Stable operational capability

Set up a safety door. After the non crushable object enters the crushing chamber, the operator can open the safety door and discharge it from the machine body to avoid damaging the crusher.

Advanced control system

The PLC control system and hydraulic power system enable intelligent production to save time and effort, achieving stable, automatic, and safe operation of the entire production line.

Previous Page

Previous Page

Cases

Related Products

ENQUIRY NOW

If you have any comments or suggestions on our products, you can leave us a message. Please fill in the correct contact information, and we will contact you as soon as possible!